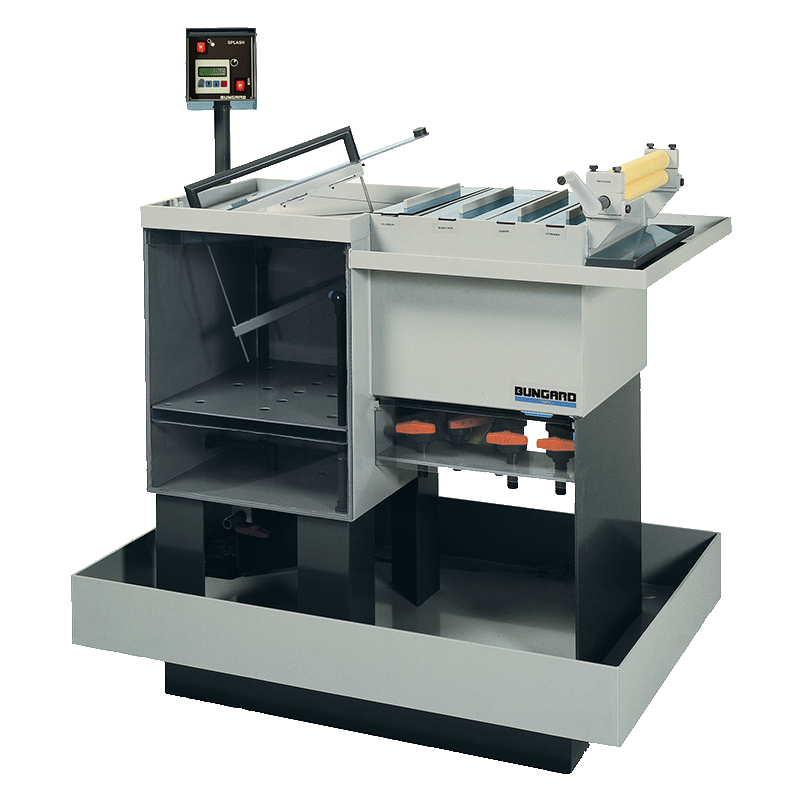

Rotation wheel etcher for double sided sheets

Titan 3500

The Titan 3500 is a double-sided spray etcher for high precision applications. In addition to the patented nozzle system, which ensures uniform wetting of the substrate, the substrate is rotated during the etching process to reliably prevent the formation of an etch shadow and uneven etching by e.g. the trace geometry. This enables structure resolutions down to 40μm with a copper thickness of 35μm.

Usable format: 350 mm x 350 mm

Dimensionen (LxWxH): 950 x 750 x 1100 mm

Working height: 1150 mm

Power: 1800 W

EN

EN  DE

DE  ES

ES  FR

FR